特斯拉 CEO 马斯克:不不不不不不要开会!

我写的越多,就越提防马斯克,因为他现在已经不满足写 Twitter 了,开始尝试发越来越长的邮件,这不由得让我很担心:这厮不会又想当编辑了吧?

我写的越多,我老板就越喜欢马斯克,毕竟哪个老板不想成为这样引领业界发展,自带光环效应,随便说一句话就让媒体干活的人呢?

为了我老板,我决定今天勉为其难再写一次马斯克,因为他的特斯拉内部信又火了……

这封信非常符合成功学的定义,大致可以分成四部分:

停产是为了多造车

这周特斯拉 Model 3 的生产线又停工了,一时间很多人又开始担心,这 3-5 天的停滞是不是又会影响销量?

马斯克表示,这次停车可是治病要治本了。

本次升级,将对之前 Model 3 生产线上一些影响装配关键环节的部分进行调整和升级,彻底对瓶颈环节进行消除,乐观估计到 5 月份,Model 3 就能相对上个月翻一倍,达到 4000 辆每周的速度。接下来呢?

我们再停工一次。

5 月份停产之后,同样再进行一次产线升级,这样就能在 6 月份实现 6000 辆/台的生产速度了。

这话可不光是说给媒体听的,马斯克甚至还手动 @ 了全体部门和供应商,要求他们在 6 月底之前单天生产出来 850 套零部件,此事可是要追责的,如果不能做到,“需要有一个非常好的理由告诉我为什么不能,并提交解决问题的计划,直接向我演示”。

多造车需要多招人

马斯克和我有个共同的优点,我们都敢于承认马斯克做错事了。

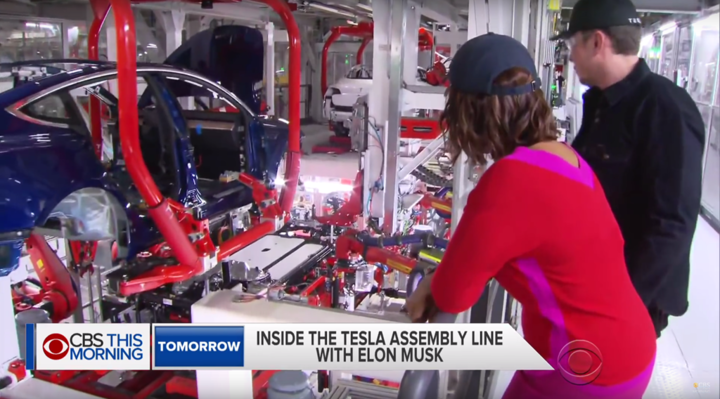

4 月 13 日,马斯克在 Twitter 上亲口承认,在特斯拉,高度依赖自动化是一个错误,人的力量被低估了。

虽然从理论上讲全部顺畅的自动化比如高于人工的效率,但自动化产线的建设也面临着两方面的问题,一是产线的调试搭配非常繁杂,很多技术问题都可能导致停工,二是在一些需要灵活性的装配环节时,人力还是具备完全机械化不具备的优势。

于是马斯克想明白了,招人呗。

在接下来的日子里,Model 3 的生产线要实现每周 7 天 24 小时不间断运行,这就使得冲压、喷涂、总装线都要多出一个班次。

人从那来呢?招聘,马斯克表示特斯拉将每周新增 400 人,持续几个星期。

虽然特斯拉的装配质量一直像企鹅的产品原创一样是重灾区,但马斯克表示,Model 3 的装配精准度必须要比其他任何车都好上 10 倍。

如果你买到的车没有达到这样的精度,别灰心,是你的测量仪器坏了。

多招人你得能赚钱

每周多 400 张嘴,吃的不都是钱么。

特别是对于特斯拉这种破产预告比产品预告还要多的企业来说,这是个大事。

于是可能之前一直看热闹的财务部门要倒霉了,马斯克“要求特斯拉财务团队梳理我们在世界各地无论多小的支出,并要求削减所有没有强烈的价值需要的东西”。

所有超过 100 万美元的支出,以及在未来 1 年里累计支出超过 100 万美元的开支,都会被暂停直到马斯克明确的同意。

马斯克狠起来连供应商都杀,下面一段过于精彩,请允许我引用原文。

“我很失望地发现现在有很多承包商公司与特斯拉纠缠在一起。通常情况下,它就像一个俄罗斯套娃,承包商,下属的分包商,再下属的分包商,知道你终于发现某个人做着实际的工作。这意味着在整个渠道中有着太多浑水摸鱼获取利益却又不干实事的人。此外,很多合同都是开放式的时间和材料,而不是定好的价格和周期,这为他们提供了磨洋工的动机,将一些很小的问题,一些小山包最终集聚成了一座高山,因为他们不想结束这一趟金钱的列车。

承包商的表现非常广泛,从非常优异到比一只喝醉的树懒还要差,所有的承包商都应该将接下来的这一周作为表现自己的优秀的最后一个机会。所有无法达到特斯拉标准的公司将会在周一被终结合同。”

对了,插播一个花絮,特斯拉对于媒体的花费也特别严格,董车会不仅每次参加特斯拉发布会的成本都是自己担负的,甚至上次特斯拉员工在美国请我吃饭请的是麦当劳。

“不好意思,我们跟媒体所有花费 50 美元以上的支出都算贿赂”。

想赚钱你得会省钱

之前有人在采访车和家老板李想的时候问到公司规模的问题,李想答曰:目前 1000 人,年底前 2000 人,2020 年突破 10000 人规格。李想表示,不担心团队规模扩张带来的管理问题,因为一切都会被制度约束住。

马斯克无疑带来了几点简单,却连我们这样一个一百多人的企业都会面临的一些问题。

关于会议:过多的会议是公司的灾难,请把会议时间尽量压短。

关于工作:如果你没有在创造价值,请立刻离开会议或者放下电话。

关于沟通:沟通应该通过最短的途径来进行,而不是指挥链。

关于问题:问题的来源主要是部门之间沟通不畅。

关于直觉:总是选择常识作为引导,死命遵守公司规定显然是荒谬的。

在我写稿子期间,已经有不少同事开始转发这个文稿到朋友圈了。

可能,他们都想让自己的老板看见吧。

下面附上由董车会全文翻译的邮件内容及英文原版。

进步、准确率以及盈利

大家好

进步

首先,祝贺一切走上正轨!我们已经连续三周每周生产2000辆以上的Model3了,三周分别为2020辆、2070辆以及上周的2250辆,同时每周有2000辆的Model S和Model X。

这个数据比特斯拉去年同期的两倍还多,而且是在重重困难下取得的一项了不起的成就。对于一个汽车公司来说,产量一年提升100%更是罕见。同时,我们在质量以及生产准确率方面也有很大的提升,这可以从积极的消费者评价上得到体现。

从今天开始(Giga工厂,Fremont工厂从明天开始),我们将暂停三至五天的生产来进行全面的升级,这应该可以让我们在下个月把Model 3 的产量提升到每周3000至4000辆。

此外,另一个于五月底进行的升级将会把我们的产量在六月底提升到每周6000辆。请注意,特斯拉的所有生产部门以及我们的供应商必须能够最迟在6月30号具有每24小时生产850个部件的能力,以此来确保Model 3 每周6000 辆的产能。

所有不能做到这一点的部门以及供应商必须解释清楚原因以及解决问题的计划,同时,需要直接向我汇报。如果任何人需要帮助以达成我们的目标,请尽快让我了解。我们一定会找到解决问题的办法。

至于我们的目标是六月份每周6000辆而不是5000辆,这是因为受到复杂的全球化产业链的影响,我们不可能有一个准确的数值,同时完全不考虑公司内部和外部零部件和生产流程的影响。实际生产的速度其实就是运转最不好的那部分的速度。

通过我们在6月底每周6000辆Model 3 的生产要求,我们将会为未来整个Model 3 系统达到每周6000辆的产量打下坚实的基础。

作为行动的一部分,Fremont工厂的 Model 3 生产线将24小时不间断运营,这意味着我们将在汽车的组装、钣金、以及油漆喷涂环节新增一个轮班,请向我们推荐任何你认为可以满足我们要求的人才。在Fremont 和 Giga 两个工厂中,我们预计每周大约新增400人,持续几个星期。

准确率

大多数 Model 3 的许多设计误差已经比世界上其它任何车都要强了。不久,我们的车将会变得更好。目前还远远不够。我们将继续努力,直到Model 3 的精准度比世界上其它任何车都要好10倍。我没有在开玩笑。

我们的车需要达到这样的准确度,如果一个车主测量汽车的尺寸、面板缝隙以及平整度,如果得到的数据不符合Model 3 的规格,那只能证明他们的测量仪器不够准确。

一些零件供应商不能够或者不愿意达到这样的精度,我理解这个追求会被一些人认为很不合理。这没关系,世界上有很多汽车公司,他们有着非常低的标准。只是道不同不相为谋而已。

盈利

外界针对特斯拉一个公正的批评是,如果你无法创造利润,即营收超过花费,那么你就不是一个真正的公司。在达到足够的规模之前,这是没有意义的,而现在特斯拉正处于飞快的扩张中。

在未来发展的道路上,我们的支出将得到严格的控制。我已经要求特斯拉财务团队梳理我们在世界各地无论多小的支出,并要求削减所有没有强烈的价值需要的东西。

所有超过100万美元的支出,或者在未来的12个月里累计支出达到100万美元的东西,将会被暂停直到得到我明确的同意。如果你是负责的管理者,请确保在我们见面之前你可以有一份详尽的对供应商的报价,包括所有的零件、人工等等。

我很失望地发现现在有很多承包商公司与特斯拉纠缠在一起。通常情况下,它就像一个俄罗斯套娃,承包商,下属的分包商,再下属的分包商,知道你终于发现某个人做着实际的工作。这意味着在整个渠道中有着太多浑水摸鱼获取利益却又不干实事的人。此外,很多合同都是开放式的时间和材料,而不是定好的价格和周期,这为他们提供了磨洋工的动机,将一些很小的问题,一些小山包最终集聚成了一座高山,因为他们不想结束这一趟金钱的列车。

承包商的表现非常广泛,从非常优异到比一只喝醉的树懒还要差,所有的承包商都应该将接下来的这一周作为表现自己的优秀的最后一个机会。所有无法达到特斯拉标准的公司将会在周一被终结合同。

顺便说说,这里有一些关于生产力的建议:

- 过多的会议是大公司的灾难,并且会随着时间的推移变得越来越糟,请从所有的大型会议中脱身,除非你认为这些会议对所有的听众都有价值,在这种情况下请把会议时间尽量压缩。

- 同时离开频繁的会议,除非你正在处理非常紧急的事务。一旦事情得到解决,会议频率应该立马降低。

- 如果你没有在创造价值,请立刻离开会议或者放下电话。离开并没有不礼貌,不礼貌的是你让其他人留在那里并且浪费他们的时间。

- 不要在特斯拉的物品、软件及流程上使用首字母缩略词或没有意义的词。通常情况下,所有需要进一步解释的东西都阻碍了交流。我们不希望人们为了在特斯拉工作而不得不背诵词汇表。

- 沟通应该通过最短的途径来进行,而不是所谓的“指挥链”。所有尝试通过“指挥链”来交流的管理者都会很快地发现他们会在别的地方工作。

- 问题的主要来源是部门间沟通不畅。解决这个问题的方法是允许所有级别之间的信息自由流动。如果为了在部门之间完成一些事情,一个人先告诉他的经理,再传给下一个经理,再传给下一个副总裁,再传给另一位副总裁,这样具体执行时就会发生超级愚蠢的事情。人们有权直接谈话并且恰当地做出正确的事情。

- 总是选择常识作为你的引导。死命遵守“公司规则”而不变通在某种特定情况下显然是荒谬的。

如果您认为应该做某些事情能让特斯拉变得更好,或者能让你更乐意去工作,请直接给我发邮件:[email protected]

感谢这支伟大团队的每一个人。

你们老板:伊隆·马斯克

Progress, Precision and Profit

Elon Musk

Everybody

Progress

First, congratulations are in order! We have now completed our third full week of producing over 2000 Model 3 vehicles. The first week was 2020, the second was 2070 and we just completed 2250 last week, along with 2000 Model S/X vehicles.

This is more than double Tesla’s weekly production rate last year and an amazing feat in the face of many challenges! It is extremely rare for an automotive company to grow the production rate by over 100% from one year to the next. Moreover, there has simultaneously been a significant improvement in quality and build accuracy, which is reflected in positive owner feedback.

Starting today at Giga and tomorrow at Fremont, we will be stopping for three to five days to do a comprehensive set of upgrades. This should set us up for Model 3 production of 3000 to 4000 per week next month.

Another set of upgrades starting in late May should be enough to unlock production capacity of 6000 Model 3 vehicles per week by the end of June. Please note that all areas of Tesla and our suppliers will be required to demonstrate a Model 3 capacity of ~6000/week by building 850 sets of car parts in 24 hours no later than June 30th.

Any Tesla department or supplier that is unable to do this will need to have a very good explanation why not, along with a plan for fixing the problem and present that to me directly. If anyone needs help achieving this, please let me know as soon as possible. We are going to find a way or make a way to get there.

The reason that the burst-build target rate is 6000 and not 5000 per week in June is that we cannot have a number with no margin for error across thousands of internally and externally produced parts and processes, amplified by a complex global logistics chain. Actual production will move as fast as the least lucky and least well-executed part of the entire Tesla production/supply chain system.

By having a Model 3 subsystem burst-build requirement of 6k by the end of June, we will lay the groundwork for achieving a steady 6k/week across the whole Model 3 system a few months later.

As part of the drive towards 6k, all Model 3 production at Fremont will move to 24/7operations. This means that we will be adding another shift to general assembly, body and paint. Please refer anyone you know who you think meets the Tesla bar for talent, drive and trust. Between Fremont and Giga, Tesla will be adding about 400 people per week for several weeks.

Precision

Most of the design tolerances of the Model 3 are already better than any other car in the world. Soon, they will all be better. This is not enough. We will keep going until the Model 3 build precision is a factor of ten better than any other car in the world. I am not kidding.

Our car needs to be designed and built with such accuracy and precision that, if an owner measures dimensions, panel gaps and flushness, and their measurements don’t match the Model 3 specs, it just means that their measuring tape is wrong.

Some parts suppliers will be unwilling or unable to achieve this level of precision. I understand that this will be considered an unreasonable request by some. That’s ok, there are lots of other car companies with much lower standards. They just can’t work with Tesla.

Profit

A fair criticism leveled at Tesla by outside critics is that you’re not a real company unless you generate a profit, meaning simply that revenue exceeds costs. It didn’t make sense to do that until reaching economies of scale, but now we are there.

Going forward, we will be far more rigorous about expenditures. I have asked the Tesla finance team to comb through every expense worldwide, no matter how small, and cut everything that doesn’t have a strong value justification.

All capital or other expenditures above a million dollars, or where a set of related expenses may accumulate to a million dollars over the next 12 months, should be considered on hold until explicitly approved by me. If you are the manager responsible, please make sure you have a detailed, first principles understanding of the supplier quote, including every line item of parts & labor, before we meet.

I have been disappointed to discover how many contractor companies are interwoven throughout Tesla. Often, it is like a Russian nesting doll of contractor, subcontractor, sub-subcontractor, etc. before you finally find someone doing actual work. This means a lot of middle-managers adding cost but not doing anything obviously useful. Also, many contracts are essentially open time & materials, not fixed price and duration, which creates an incentive to turn molehills into mountains, as they never want to end the money train.

There is a very wide range of contractor performance, from excellent to worse than a drunken sloth. All contracting companies should consider the coming week to be a final opportunity to demonstrate excellence. Any that fail to meet the Tesla standard of excellence will have their contracts ended on Monday.

Btw, here are a few productivity recommendations:

– Excessive meetings are the blight of big companies and almost always get worse over time. Please get of all large meetings, unless you’re certain they are providing value to the whole audience, in which case keep them very short.

– Also get rid of frequent meetings, unless you are dealing with an extremely urgent matter. Meeting frequency should drop rapidly once the urgent matter is resolved.

– Walk out of a meeting or drop off a call as soon as it is obvious you aren’t adding value. It is not rude to leave, it is rude to make someone stay and waste their time.

– Don’t use acronyms or nonsense words for objects, software or processes at Tesla. In general, anything that requires an explanation inhibits communication. We don’t want people to have to memorize a glossary just to function at Tesla.

– Communication should travel via the shortest path necessary to get the job done, not through the “chain of command”. Any manager who attempts to enforce chain of command communication will soon find themselves working elsewhere.

– A major source of issues is poor communication between depts. The way to solve this is allow free flow of information between all levels. If, in order to get something done between depts, an individual contributor has to talk to their manager, who talks to a director, who talks to a VP, who talks to another VP, who talks to a director, who talks to a manager, who talks to someone doing the actual work, then super dumb things will happen. It must be ok for people to talk directly and just make the right thing happen.

– In general, always pick common sense as your guide. If following a “company rule” is obviously ridiculous in a particular situation, such that it would make for a great Dilbert cartoon, then the rule should change.

If there is something you think should be done to make Tesla execute better or allow you to look forward to coming to work more (same thing in the long term), please send a note to [redacted]

Thanks for being such a kickass team and accomplishing miracles every day. It matters. We are burning the midnight oil to burn the midnight oil.

Elon